Tripping & Stripping

Incidents often happen when things change hence management of change is important. Change is continually happening when you are tripping regardless of whether you are tripping in or out of the well. The most obvious change taking place during tripping operations is the volume of pipe in the well and this must be carefully tracked using an approved trip sheet.

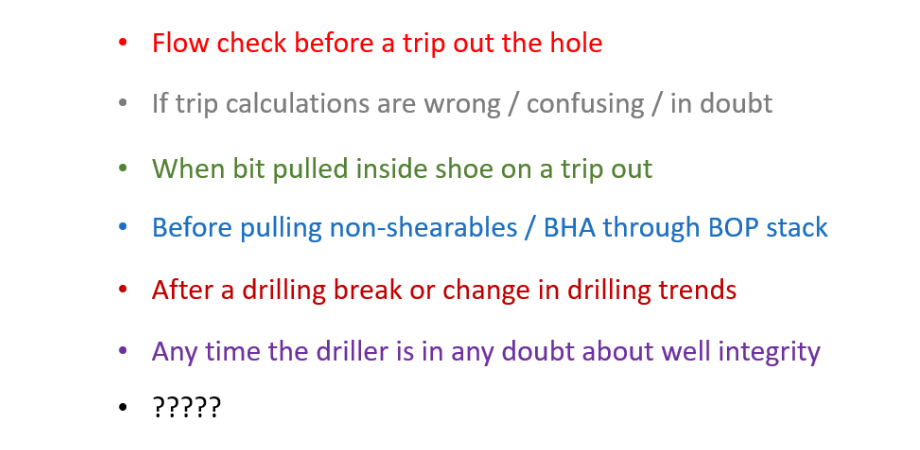

Before starting a trip out of the well a flow check should be conducted to ensure the well is not flowing – hydrostatic pressure is greater than formation pressure (you have primary well control). Flow checks are commonly conducted:

During all tripping operations the trip tank should be circulating over the top of the well to ensure the annulus is always kept full of mud. This will help ensure there is no reduction to the hydrostatic pressure in the annulus.

When pipe is removed from the well the trip tank volume will go down as mud replaces what you remove from the well (Archimedes ‘Eureka’ moment - when he got in the bath he knew how to figure out how much gold there was – Google it if you want to know).

How much volume the trip tank changes by will depend on whether you are tripping ‘dry’ or ‘wet’. Tripping ‘dry’ you only remove pipe from the well so the trip tank should go down by a volume equal to the volume of metal you have pulled from the well (metal displacement in bbl/ft times the length in feet of pipe pulled). If you are tripping ‘wet’ then the trip tank should go down by a volume equal to the volume of metal you have pulled from the well plus the volume of mud it would take to fill that pipe (closed end displacement in bbl/ft times the length in feet of pipe pulled).

Trip sheet calculations can be worked out in advance using your pipe tally and then actual displacement is checked against calculated displacement. This is done per stand initially on a trip out for the first five or ten stands and then every five stands thereafter. If there is a discrepancy between calculated and actual displacement then the trip should be stopped, and a flow check conducted.

If the well is flowing then it should be shut in by isolating the drill string first using a drill string safety valve and then the annulus following your company approved procedure. How could an influx have gotten in on the trip given that you flow checked before starting the trip and it wasn’t flowing? What kill mud weight will be needed to restore primary well control?

If the well is not flowing then you will have to investigate why the calculations do not tally. This will usually mean you have to get back to bottom and circulate bottoms up. If there is an influx in the well then simply running back to bottom will displace the influx into the small diameter drill collar to open hole annulus which in turn will lead to an additional decrease in BHP which in turn could cause the well to properly kick on you.

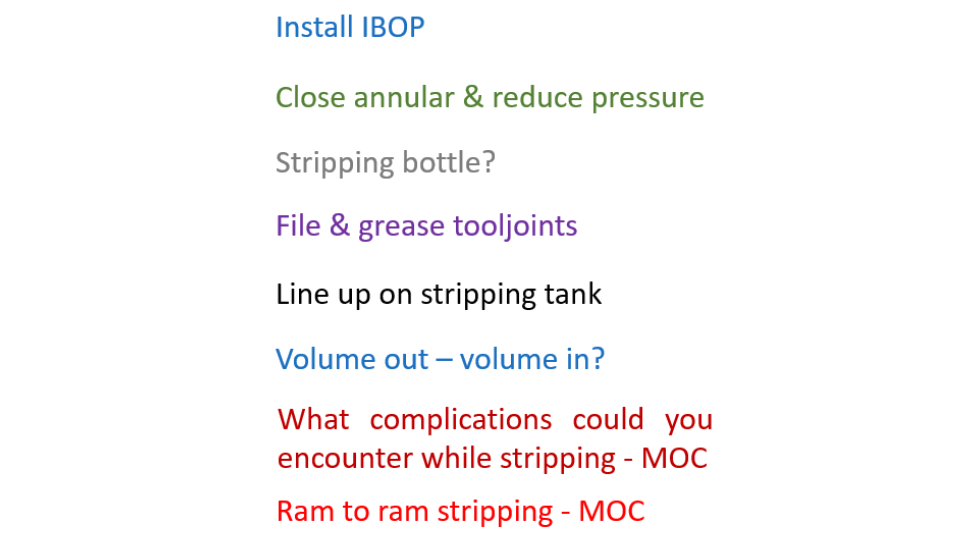

You may have to consider stripping back to bottom. Once again stripping operations will be detailed in your own company procedures but will include things like:

The question there regarding volume out and volume in. As you are stripping into the well then a volume equal to closed end displacement for the length of pipe stripped in should be bled from the well. The pipe should be filled with a volume equal to the volume of pipe capacity stripped in.

Trip (or strip) monitoring volume calculations require a degree of care (same as the kill sheet volume calculations) but they should be relatively straight forward – .

This week you might have to calculate what would happen if you were doing bad practice on a trip out the well i.e. not keeping it full of mud. Firstly always have the trip tank circulating over the top of the well during a trip, continually monitor actual versus calculated and finally don’t forget you will need to fill/empty the trip tank from time to time – manage and measure this change carefully.

There are six tripping formulas that can be used to calculate what happens when you do the wrong thing on a trip, and they are formulas 19 to 24.

The first two (19 & 20) calculate the pressure drop per foot tripping ‘dry’ or ‘wet’ without hole fill. You’ll have to multiply the answer to the formula by the length of pipe pulled to get total pressure drop.

The next two (21 & 22) calculate the level drop if you pull all the remaining collars from the well without hole fill. Note is it level drop in feet – you’ll need to work out the hydrostatic loss using formula 1. The flag is the word ‘collar’ or the word ‘bit’ in the question. The other ‘tripping’ formulas do not work for a collar question.

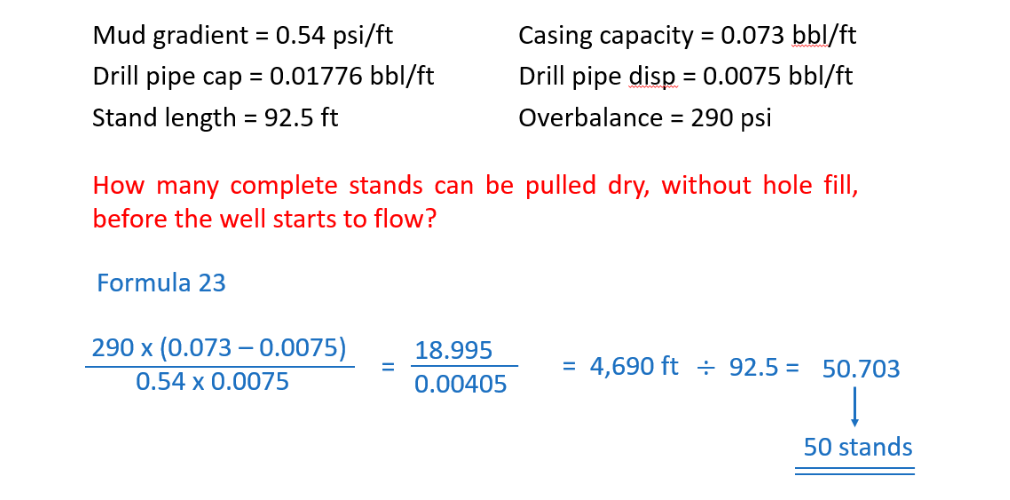

Finally you could be asked to work out how many compete stands can be pulled without hole fill before the well flows (overbalance is lost) – whole stands as calculated – do not round up.

Those calculations require care and attention to detail. Set your calculation out on some blank paper before reaching for the calculator. Do the calculations in stages and do not round until the very end – never use a rounded answer part way through a calculation.

You could also be asked questions with respect to slugs. Firstly don’t get sucked into a calculation to work out the reduction in BHP due to the slug! There is no reduction to BHP. Pick zero.

You might be asked to work out the pit gain due to the slug U-tubing into place. Formula 26 does this and remember it can be flipped to make it calculator friendly:

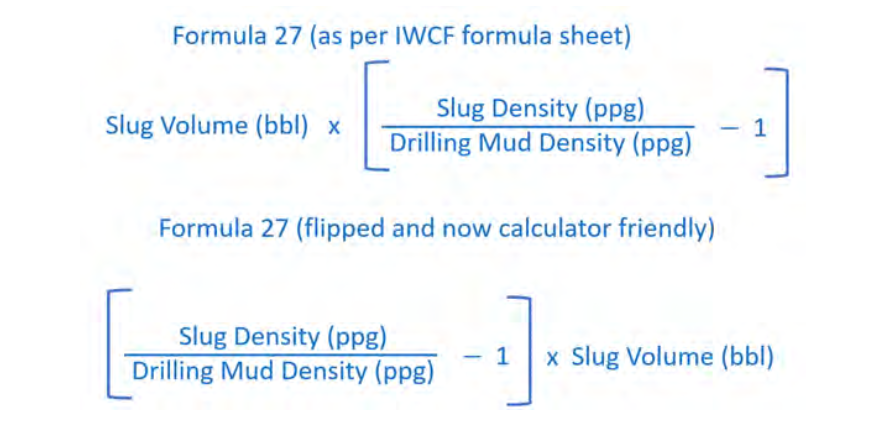

Finally you might be asked to calculate the level drop in the pipe after the slug has settled. The answer to formula 27 is the volume of empty pipe. Bbl divided by bbl/ft gives feet – pit gain in bbl divided by pipe capacity in bbl/ft will give you the level drop inside the pipe.